Channel Partners

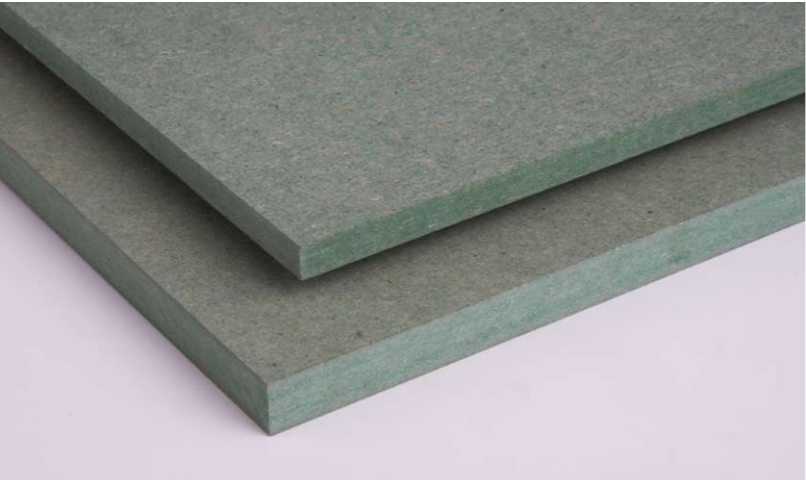

Made of rubberwood with special high-moisture resistant adhesive and wood fibers to render > 800 Kg/m3 density, HDF-HMR (V313) offers high durability that can bear three times higher weight and pressure than most MDF. The material is highly resistant to moisture, making it a suitable alternative for built-in kitchen furniture, flooring and doors.

Key Features

– Durable material provides intensive support against pressure.

– Sturdier structure than MDF.

– Refine & Smooth Surface

– Contains a moisture resistance rate greater than most MDF.

– Particularly designed for interior use including Built-in kitchen, Door skin, High pressure laminated flooring.

Why Green Dye?

The “green dye” is a globally recognized mark of identification and classification, incorporated into the core of the HMR Boards during production, to differentiate the product and ensure proper application and handling.

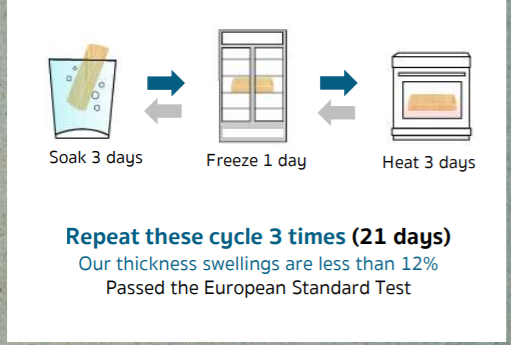

Passed V313 Test

Product Specifications:

| Specs | |

| Thickness | 2.7mm |

| Sheet Size | 2100mm * 2600 mm |

| Per Sheet Weight | 12.60kg Approx |

| Per Sheet Sqft | 58.78 |

| Pallet | |

| Dimensions (L*W*H) | 8.54 Ft * 6.91Ft * 2.83Ft |

| Weight | 3358.8 kgs |

| No of Pieces | 270 |

| Sqft | 15870.6 Sqft |

Sawn Timber

- New Zealand Pine Wood

- Malaysian Red Meranti

- Malaysian Yellow Meranti

- Malaysian Kapur Sal

- Keurig

- African Hardwood

- Teak

KD Lumber

Panel Products

- Teak Solid Panel Doors

- Solid Panel Doors

- Door Frames (Chokhat)

- Wall Panelling

- Plywood (Utility Grade)

- Plywood (Premium Grade)

- Plywood (Economical Grade)

- Plywood (Commercial )

- Plywood (Shuttering)

- HDHMR Sheet